Step.1

Procurement of the wool

The process of rug making starts by shearing the sheep and extracting the natural wool.

Wool straight off a sheep must be cleaned and scoured; a process of cleaning the greasy wool. For natural silk rugs, the silk is extracted from silkworms.

Step.2

Spinning of the wool

Spinning is the process of transforming the wool by twisting the fibres together to form yarn.

Method in spinning the wool consists of using a spinning wheel.

Step.3

Dyeing the wool

Once the raw wool has been spun to obtain yarn, it will be dyed in various colours needed for that particular rug.

Using chemical dyes

To produce the exact desired colour the dye is heated to a near boiling tempeture.

Once this procedure is complete,yarn is kept into the sunlight for dry.

Step.4

Drawing Design

Before manufacturing rugs design is sketched on graph paper.

And marked with colours in different columns for the weavers to follow.

Step.5

Knotting the rug

Knotting the rug is the crucial part where real talent of the weaver will be appreciated.

The finer and more homogeneous the knots are, the higher quality the rug will be. Obviously, the finer the knots are, the more time it will take to finish the rug.

Step.6

Cut the rug from the loom and trim the pile

Once the rug is finished it will be cut from the loom. The pile will then be trimmed using special scissors in order to have a homogeneous length of pile.

Step.7

Washing the rug & Drying

As the rug was always attached to the loom, it tends to be hard. The final step of rug making consists of washing it at least 2 or 3 times in order to wash the wool and get a soft rug ready to be used.

Finally, the carpet needs to be dried properly away from the sun light so that the colours can stabilize.

Step.8

Stretching

After washing and drying, the rugs are stretched from all four sides using hooks. It helps in maintaining the perfect square shape of the rug.

Step.9

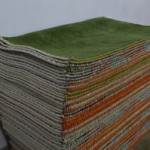

Final Finishing

The rug should be trimmed again to remove unusual yarn. After vacuum cleaning, it is packed with environment friendly packing materials. Now the rug is ready to be shipped.

Step.10

Lastly, the rug is measured,rolled, packaged and shipped for sale.